Fiber Optic Transceiver Cleaning Guide

- Posted on March 3, 2017

- by HiFiber.com

- Tags: SFP, Fiber Optic Cleaning, transceiver Cleaning, transceiver modules

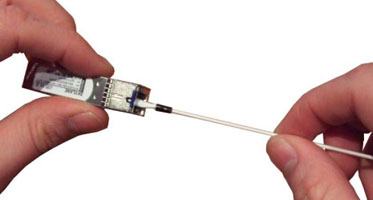

Fiber optic cleaning is highly recommended for all fiber optic connectors in a data center in order to reduce link failures and unnecessary replacement of expensive and critical network components and equipment. As an important component in a fiber link, the interface of fiber optic transceiver should also be cleaned. This tutorial is a cleaning guide for fiber optic transceivers.

Common Source of Contaminants in Transceiver Optical Port

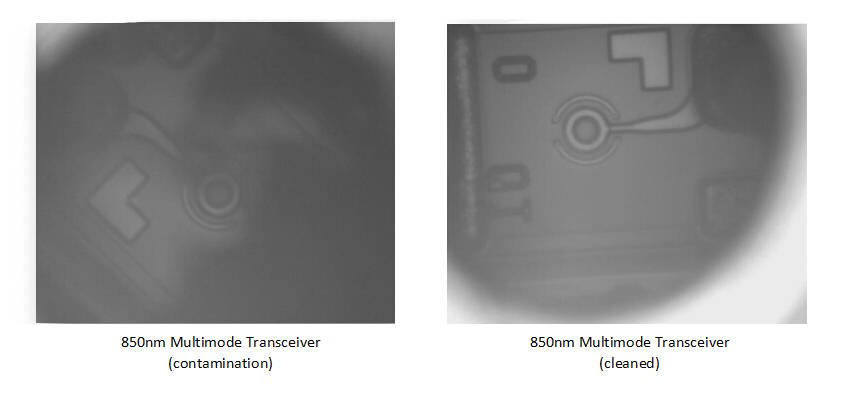

Fiber optic transceiver transmits and receives optical signals through the optical ports. According to the connector types of the used patch cord, there are generally LC, SC, and MTP port designed with today's commonly used form factors. The most common source of contaminants in the optical port in a fiber optic transceiver is debris picked up on the ferrules of the optical connectors. In addition, using contaminated fiber patch cord or shoddy fiber patch cord, also leads the optical port of fiber optic transceiver module to be contaminated. The picture below shows the comparison of transceivers with contaminated and cleaned optical interface.

When to Clean?

We have always emphasized that the connector end-face of fiber patch cord should be always cleaned before connection. However, this does not seem to apply to fiber optic transceivers. The optical ports of fiber optic transceivers have less risk of being contaminated compared to fiber patch cords. Thus, they should not require frequent cleaning unless there is an issue. In a practical application, the optical port of a fiber optic transceiver should be cleaned in the case of that you have cleaned your connectors, but still experience low-power output from an optical transceiver or a fault signal from your equipment.

Warm Tips: The optical ports of new fiber optic transceivers from good and reliable vendors should be cleaned, and inserted with the dust caps before delivery. Thus, in most cases, they should not require to be cleaned (of course, it is no problem if you really want a cleaning for them).

How to Clean?

If the source of contaminants is as the first case mentioned in section one, using an alcohol swab or lint-free absorbent wipes to clean the ferrules of the optical connector is very necessary. If it is contaminated with dust or particles, the best way to clean the optical port of a transceiver is to use the air duster (also called clean dry air) to blow away small dust particles. In general, the most common cleaning procedure is shown as below:

- Remove the dust cap from the optical transceiver.

- Use an air duster to remove any dirt or particles.

- Insert a lint-free stick of the appropriate size (2.5 mm or 1.25 mm) and turn clockwise. Dry cleaning is generally recommended here. Thus, don't use alcohol-based cleaning sticks.

- Repeat steps 2 and 3 if necessary.

- Remove the lint-free stick and reinsert the dust cap to the transceiver. Always keep the dust cap inserted in the transceiver when not in use.

- Place the transceiver on a clean and static-free area, such as an antistatic mat.

Summary

Fiber optic transceivers play an important role in transmitting and receiving optical signals in fiber link. The contamination of the optical ports of fiber optic transceiver may cause network breakdown and link failures. Thus, proper cleaning is necessary to ensure the fiber transmission performance. Cleaning for optical ports of fiber optic transceivers is done when there is an error on port. Dry cleaning is generally recommended to use with air duster and lint-free sticks. In addition, in order to avoid cross contamination, fiber patch cords should be always cleaned before connecting to the transceivers.

Popular Posts

-

Tight-Buffered Cable vs. Loose-Tube Gel-Filled Cable

Tight-buffered fiber optic cable is typically thought to be used for indoor applications while loose-tube gel-filled cable is for ...

-

What Should Be Considered When Buying Tight-Buffered Distribution Cables

When selecting the correct tight-buffered distribution cable for indoor or indoor/outdoor installation, the first consideration wi...

Latest Posts

-

Fiber Optic Transceiver Cleaning Guide

Fiber optic cleaning is highly recommended for all fiber optic connectors in a data center in order to reduce link failures and un...

-

How to Stack Two CWDM Mux/Demux Via Expansion Port?

Coarse Wavelength Division Multiplexing (CWDM) enables carriers to deliver more services over their existing optical fiber infrast...

-

Bend Insensitive Fiber Cable for High Quality and Low Loss Transmission

As we all know, fiber optic cable has been widely used in the telecommunication area. During fiber cable installation and maintena...